Nooca FOS-D Bambooyin toos ah oo Saliid Saliid ah

Faahfaahin

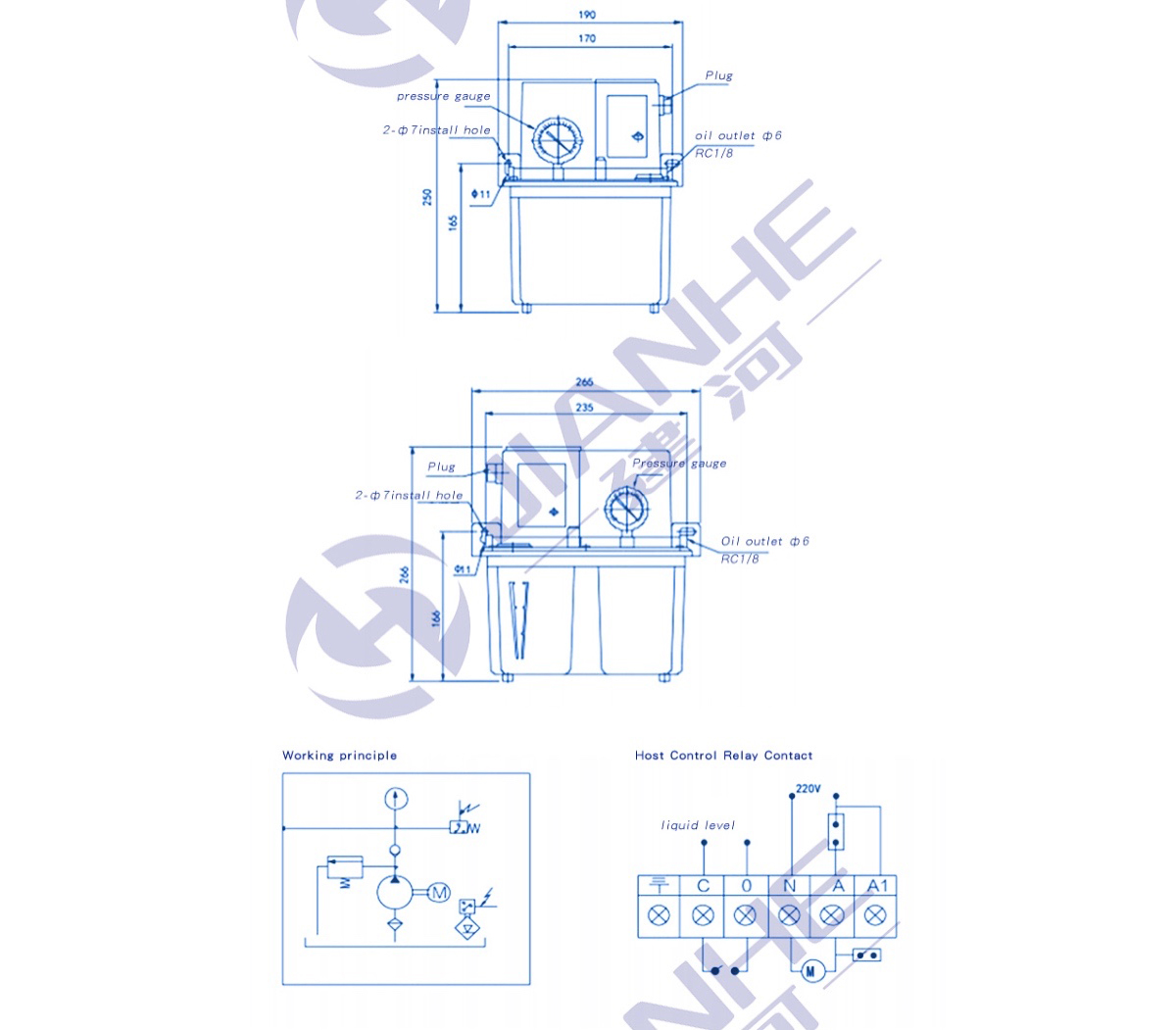

Nooca FOS-D waxaa iska leh bamka saliidaynta iska caabbinta korantada, kaas oo loo isticmaalo nidaamka saliidaynta iska caabinta.Waa nidaam saliidayneed oo hooseeya, kaas oo u qaybsan bamka saliidda xilliyeed iyo bamka sifaynta joogtada ah.Midka hore wuxuu u qaybiyaa saliidda saliidda sifaynta kasta si siman iyada oo loo marayo qayb cabbir.Point, garwaaqso silica xilliyeedka, kan dambe waa bamka saliidda si joogto ah u shaqeeya, saliidda saliidda waxaa loo qaybiyaa dhibic kasta oo saliid ah iyada oo loo marayo qayb ka mid ah kantaroolka si loo xaqiijiyo lubrication joogto ah.

Waxa lagu gartaa qaab-dhismeed kooban, hawl-gal iyo dayactir ku habboon, iyo sahayda saliidda barta saliidda waxa lagu maamulaa qaybo cabbiraadda ama qaybaha xakamaynta, saliiddana si siman ayaa loo bixiyaa.Midda saddexaad waa in ay ku habboon tahay in la kordhiyo ama la yareeyo barta saliidda.Ugu dambeyntii, shaabadda gaarka ah Naqshaduhu waxay si wax ku ool ah uga hortagi karaan daadinta xiriirka.

Faahfaahin

Waa bamka saliidaynta ee u kaxeeya piston si uu u soo celiyo oo uu saliidda ugu qaado iyada oo loo marayo awoodda korantada ee beddelka ah ee ay dhaliso goobta korantada.Waxay leedahay sifooyinka qaab-dhismeedka macquulka ah, waxqabad la isku halleyn karo, muuqaal qurux badan, hawlo dhamaystiran iyo waxqabadka qiimaha sare leh.Waxay bedeli kartaa bamka piston-ka ee korontada ku shaqeeya waxayna ku habboon tahay sifaynta dhexe ee qalabka farsamada yar yar oo leh dhibco yar oo saliid ah.

Halbeegga Alaabta

| Qaabka | Socodka (ml/min) | duridda ugu badan cadaadis (MPa) | Saliid dhibic | Viscosity Saliidda (mm2/s) | Matoorka | Taangiga (L) | Miisaanka | |||

| Votage | awood (W) | inta jeer (HZ) | ||||||||

| FOS-R-2II | Atomatic -Volumeteric | 100 | 2 | 1-180 | 20-230 | AC220 | 20 | 50/60 | 2 | 2.5 |

| FOS-R-3II | Atomatic -Volumeteric | 3 | 3.5 | |||||||

| FOS-R-9II | Atomatic -Volumeteric | 9 | 6.5 | |||||||

| FOS-D-2II | Atomatic - iska caabin | 2 | 2.5 | |||||||

| FOS-D-3II | Atomatic - iska caabin | 3 | 3.5 | |||||||

| FOS-D-9II | Atomatic - iska caabin | 9 | 6 | |||||||

Samaynta bamka saliidda saliidda ee tooska ah ee qalabka mashiinka CNC:

Ku qalabaysan beddelka heerka dareeraha, kontaroole, iyo furaha orodka.Marka loo eego nidaamyada kala duwan, furaha cadaadiska ayaa sidoo kale la habeyn karaa.Digniinta la kantaroolo waxa kale oo si toos ah loogu xidhi karaa adeegaha martida loo yahay PLC.Waxay xaqiijin kartaa la socodka heerka saliidda ee haanta saliidda iyo cadaadiska nidaamka bixinta saliidda iyo dejinta wareegga saliidda.

Alaabtan waxaa si weyn loogu isticmaalaa hababka saliidaynta ee kala duwan ee qalabka mashiinka, foornada, dharka, daabacaadda, balaastikada, caag, dhismaha, injineernimada, warshadaha iftiinka iyo qalabka kale ee farsamada.