Nooca FOP-D Bambooyin toos ah oo Saliid Saliid ah

Faahfaahin

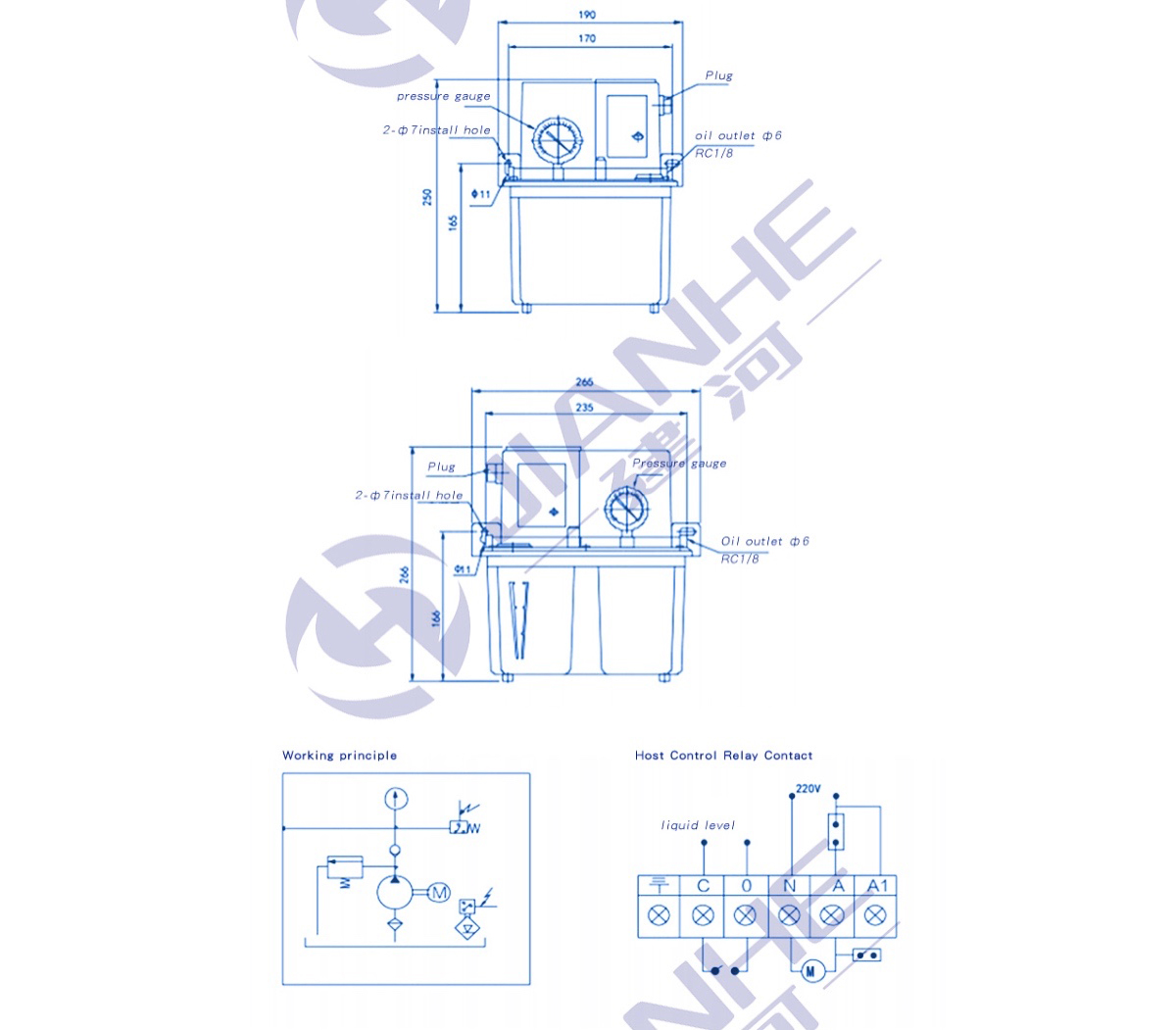

Nooca FOP-R waa bamka saliidaynta mugga korantada, kaas oo loo isticmaalo hababka saliidaynta mugga.VNidaamyada sifaynta olumetric waa nidaam sifeyn xilliyeed, kaas oo ka kooban bamka saliidda, saliida tirada, qalabyada dhuumaha iyo qayb ka mid ah kantaroolka, taas oo si sax ah u qiyaasi karta dhibic kasta oo saliid ah hadba sida loogu baahdo.Saliidda, heerka khaladku waa qiyaastii 5%, Midda koowaad waa in ay ku habboon tahay in la kordhiyo ama la yareeyo barta saliidda, tan labaadna waa sahayda saxda ah ee saliidda, ta saddexaadna waxay ogaan kartaa cadaadiska nidaamka, iyo sahayda saliidda waa la isku halayn karo.

Faahfaahin

Waa bamka saliidaynta ee u kaxeeya piston si uu u soo celiyo oo uu saliidda ugu qaado iyada oo loo marayo awoodda korantada ee beddelka ah ee ay dhaliso goobta korantada.Waxay leedahay sifooyinka qaab-dhismeedka macquulka ah, waxqabad la isku halleyn karo, muuqaal qurux badan, hawlo dhamaystiran iyo waxqabadka qiimaha sare leh.Waxay bedeli kartaa bamka piston-ka ee korontada ku shaqeeya waxayna ku habboon tahay sifaynta dhexe ee qalabka farsamada yar yar oo leh dhibco yar oo saliid ah.

Halbeegga Alaabta

| Qaabka | Socodka (ml/min) | duridda ugu badan cadaadis (MPa) | Saliid dhibic | Viscosity Saliidda (mm2/s) | Matoorka | Taangiga (L) | Miisaanka | |||

| Votage | awood (W) | inta jeer (HZ) | ||||||||

| FOS-R-2II | Atomatic -Volumeteric | 100 | 2 | 1-180 | 20-230 | AC220 | 20 | 50/60 | 2 | 2.5 |

| FOS-R-3II | Atomatic -Volumeteric | 3 | 3.5 | |||||||

| FOS-R-9II | Atomatic -Volumeteric | 9 | 6.5 | |||||||

| FOS-D-2II | Atomatic - iska caabin | 2 | 2.5 | |||||||

| FOS-D-3II | Atomatic - iska caabin | 3 | 3.5 | |||||||

| FOS-D-9II | Atomatic - iska caabin | 9 | 6 | |||||||

Samaynta bamka saliidda saliidda ee tooska ah ee qalabka mashiinka CNC:

Ku qalabaysan beddelka heerka dareeraha, kontaroole, iyo furaha orodka.Marka loo eego nidaamyada kala duwan, furaha cadaadiska ayaa sidoo kale la habeyn karaa.Digniinta la kantaroolo waxa kale oo si toos ah loogu xidhi karaa adeegaha martida loo yahay PLC.Waxay xaqiijin kartaa la socodka heerka saliidda ee haanta saliidda iyo cadaadiska nidaamka bixinta saliidda iyo dejinta wareegga saliidda.

Alaabtan waxaa si weyn loogu isticmaalaa hababka saliidaynta ee kala duwan ee qalabka mashiinka, foornada, dharka, daabacaadda, balaastikada, caag, dhismaha, injineernimada, warshadaha iftiinka iyo qalabka kale ee farsamada.